Final assembly of the 415-C elevator

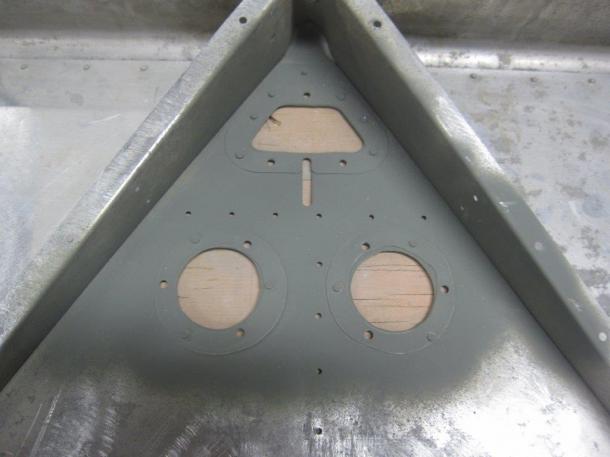

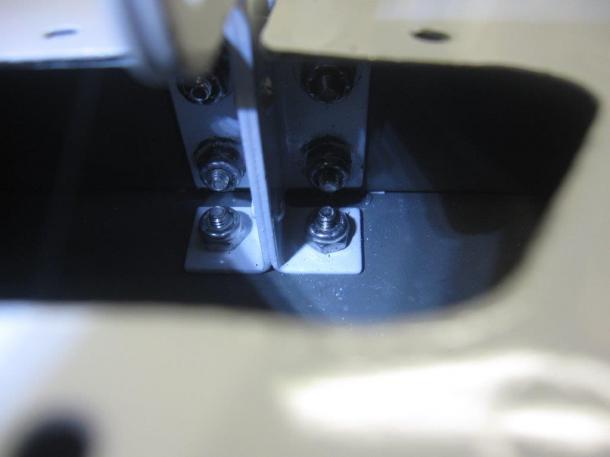

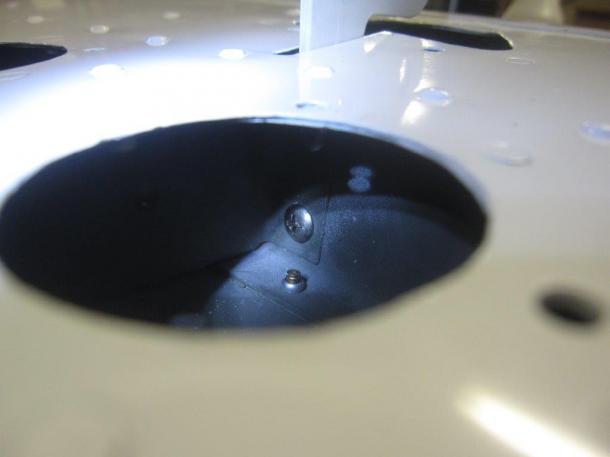

...cleaned and primed exterior of skin with self-etching primer, then painted gloss white acrylic enamel. Installed elevator control horn with new stainless steel screws and nuts; remounted elevator to airplane and rigged trim tab, and installed inspection hole covers. ...cleaned and painted the interior skin and ribs with self-etching primer; made and riveted in reinforcement rings around inspection holes; riveted horn rib, center rib and new mounting channel into the bottom skin with AN470AD and AN426AD rivets; then riveted the top skin back on using AN470AD and AN426AD rivets around the edge, and Cherry Max rivets in the blind locations for the horn rib, center rib and mounting channel.

As the du Pont DR-127A explosive (blind) rivet, or equivalent, is not readily available, and some of the holes from the explosive rivets were larger than 1/8" diameter, I used Cherry Max CR3243-4-1,-2,-3 .140" oversized rivets to replace them.

I recommend either to substitute the stainless steel screws and nuts with cadmium plated aircraft grade screws or apply primer to the stainless steel screws as well. Stainless steel while itself not corroding will corrode surrounding metal of lower position in the galvanic corrosion table. the editor

Willie Topken

| << previous |